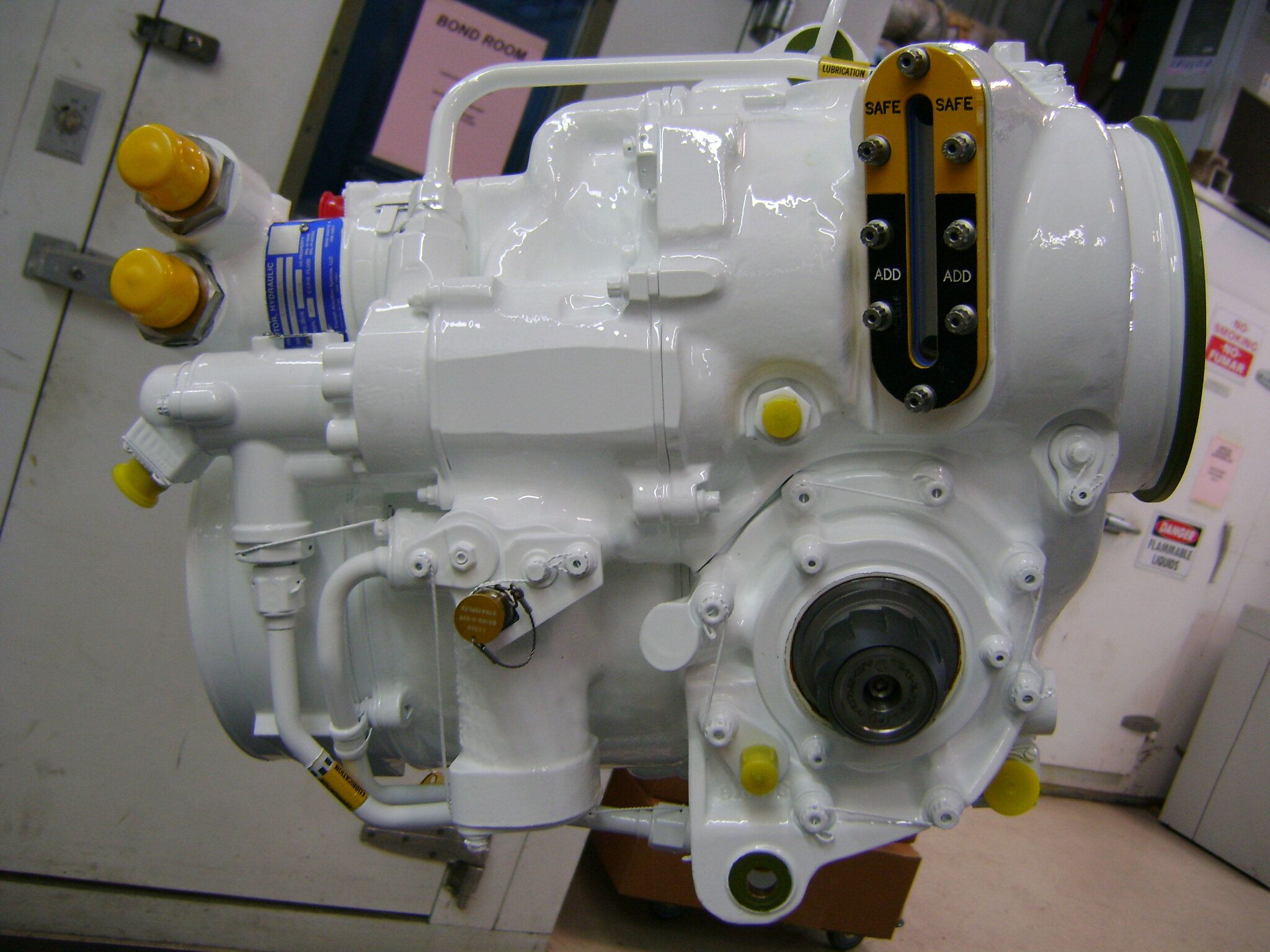

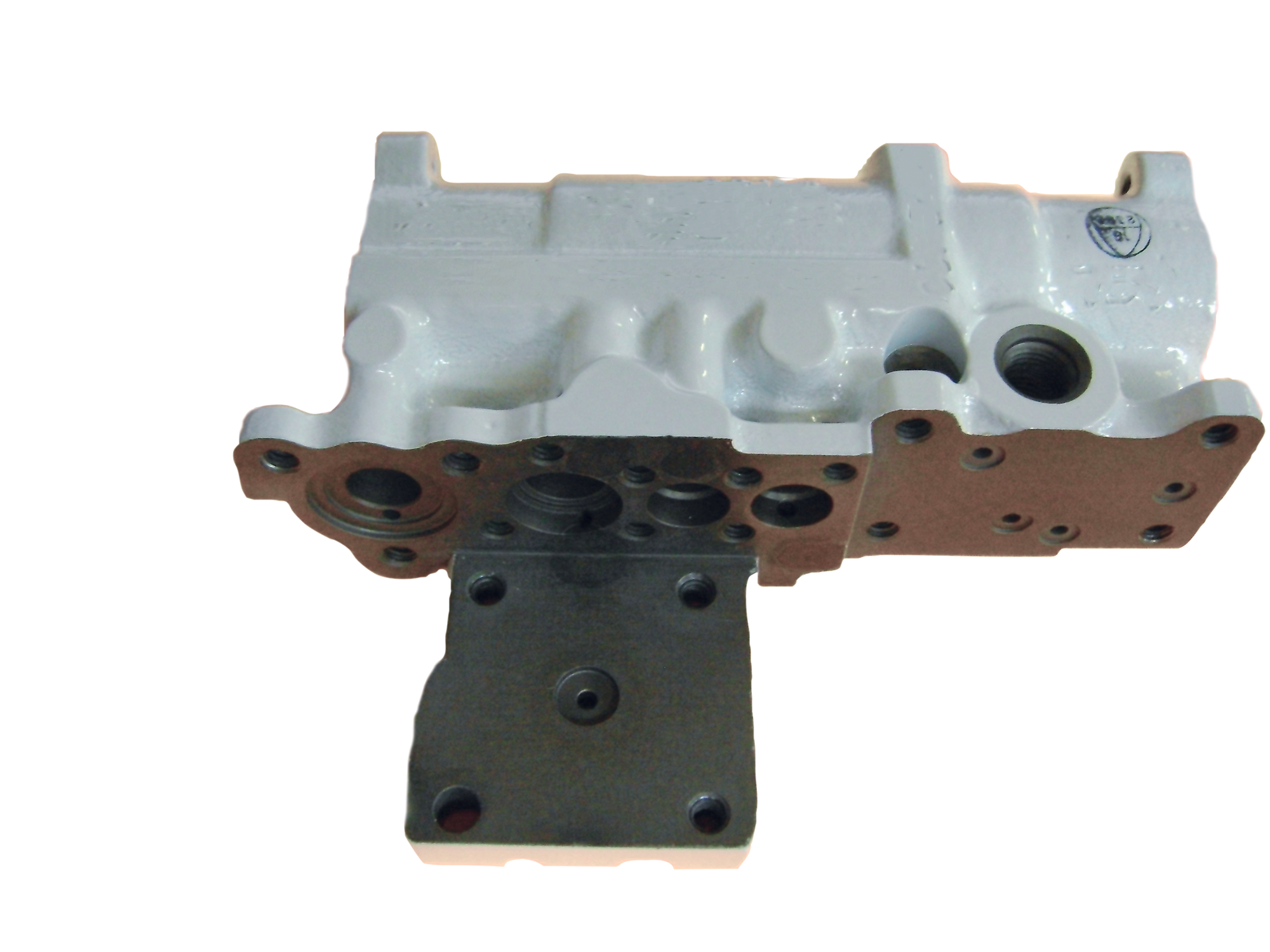

Serving the Aerospace & Defense Industry Since 1978, AID Aerospace Specializes in Low-Volume, High-Complexity Parts

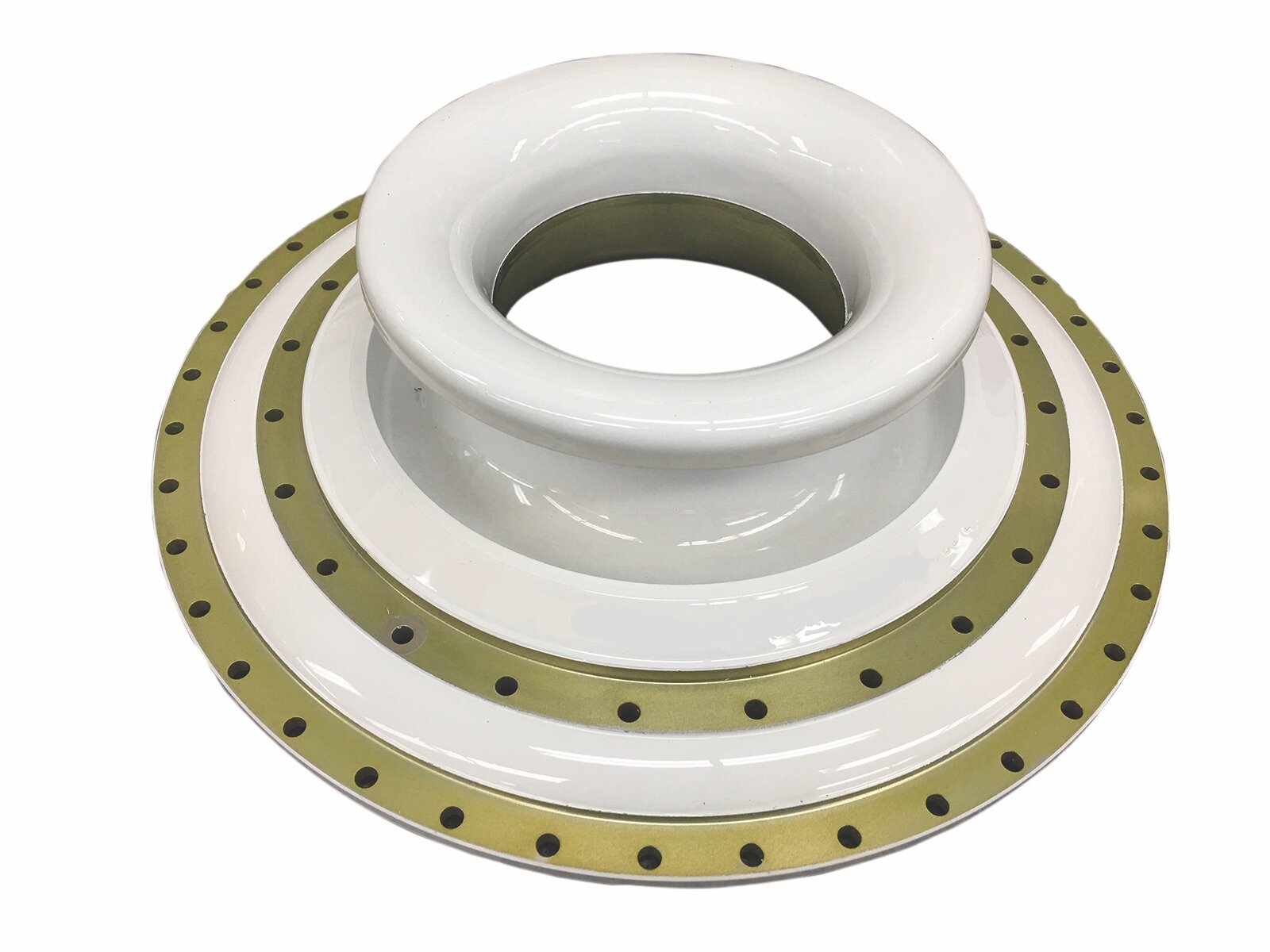

PLATING & FINISHING SERVICES

We process your parts to your exact engineering specifications. Our plating & finishing services include wet painting, dry film lubricants, powder coating, chemfilm, passivation and a host of additional part prep services.

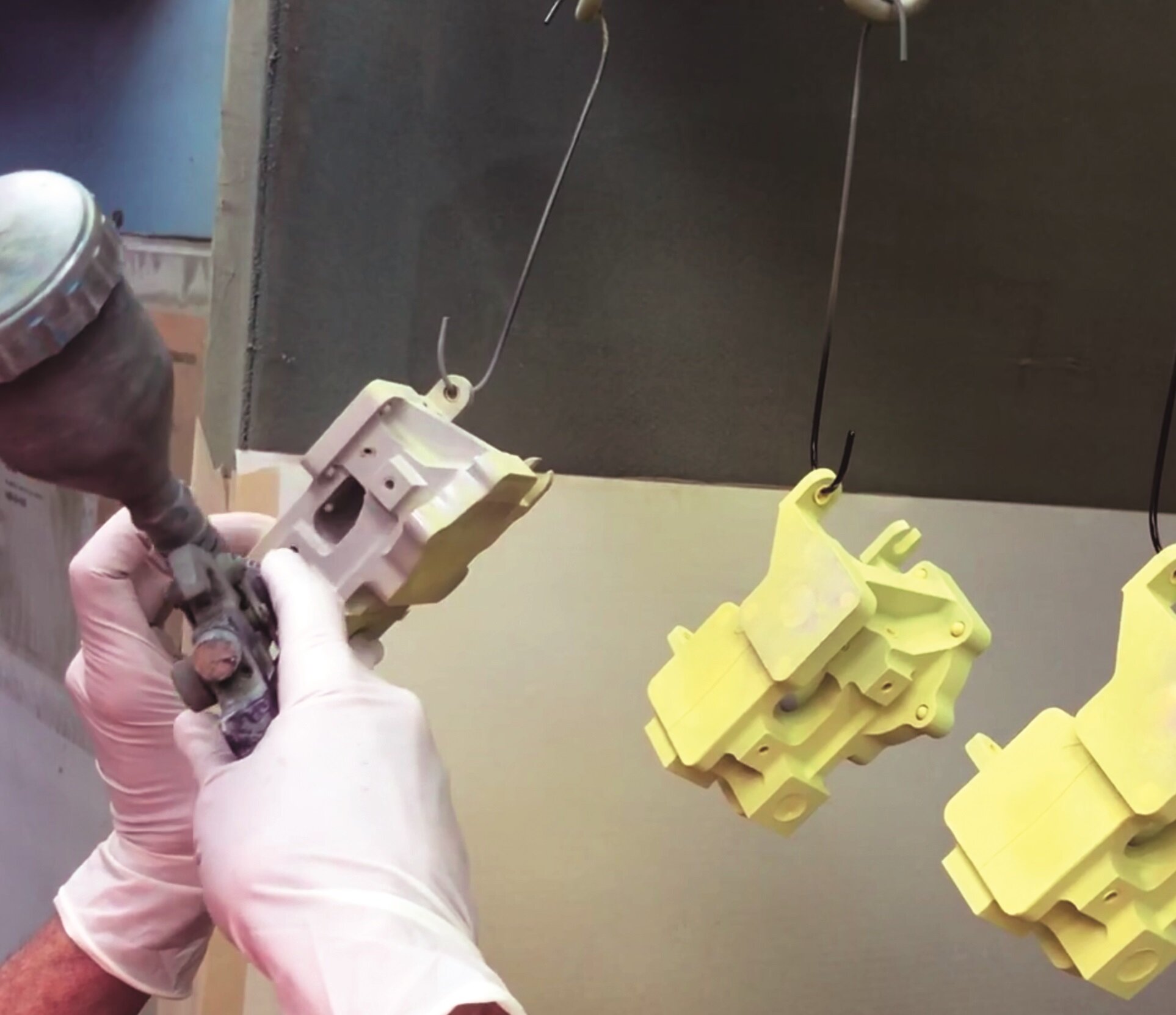

LIQUID PAINTING

Our core expertise is in application of liquid coatings to aerospace, military, and commercial hardware. We apply epoxies, polyurethanes, enamels, lacquers and nearly any other liquid coating you might need.

DRY FILM LUBRICANTS

We can apply all dry lubricant coatings to your parts per your engineering specifications. We routinely apply Teflon, graphite, molybdenum disulfide, titanium disulfide and many others for low friction and wear resistance in critical part locations.

POWDER COATING

Our powder coating system includes a hanging parts conveyor that directly connects our paint booths to our large curing oven allowing continuous part coating and eliminating part handling after powder is applied. We routinely use polyesters, epoxies, nylons, vinyl, Kynar, Halar, Teflon and many other types of powder.

SELECTED PARTS GALLERY